The Power of Parchment

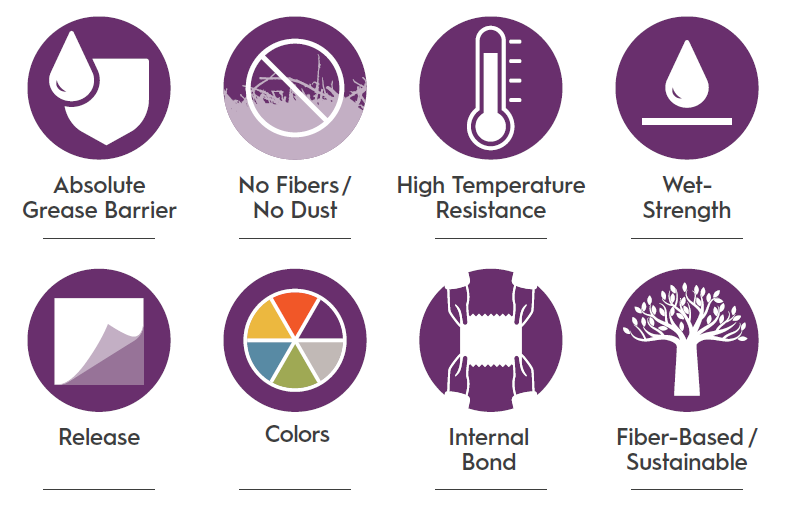

The Genuine Vegetable Parchment Technology supports the most demanding and sensitive usages in various industrial applications.

From innovation to production to consumer applications; discover where the Power of Parchment is harnessed today and its main advantages.