Join us at the 25th WFHSS World Sterilization Congress

Santiago, Chile, November 20-23, 2024

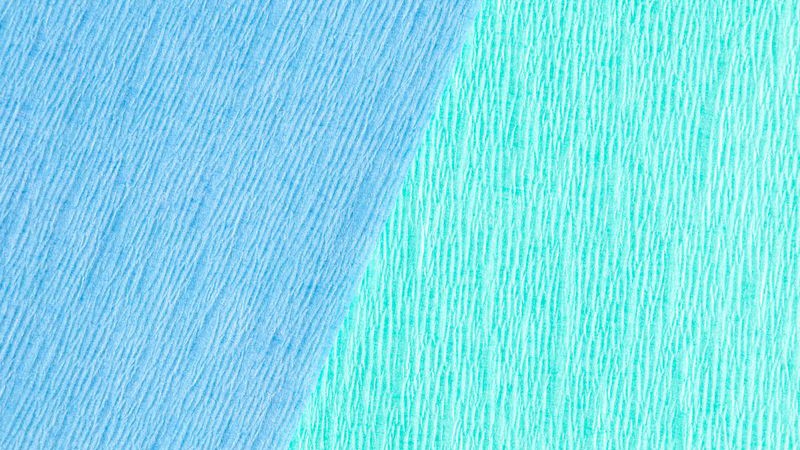

Reliance® crepe paper meets all requirements for safe and reliable wrapping, combining excellent sterility maintenance and bacterial barrier. The different colors and basis weights can accommodate diverse sterile barrier systems (SBS) requirements.

Reliance® wetlaid nonwovens, composed of cellulose, synthetic binder and PET fibers, create a tortuous path for excellent sterility maintenance. Thanks to its composition, this technology is softer and stronger, allowing to better meet end users’ requirements.

Reliance® wetlaid nonwovens, available in two colors and three basis weights, are micrexed for increased drapeability and comfort.

Ahlstrom-Munksjö Reliance® SMS (Spunbond Meltblown Spunbond) is 100% polypropylene and treated to resist charge build-up. It does not contain cellulose or synthetic binder and its composition makes this technology especially suitable for the most demanding uses, both for inner and outer wraps.

Reliance® SMS is available in two colors and six basis weights to satisfy different user requirements.

Reliance® Solo non-sequential wrapping system offers flexible and simplified wrapping.

The two bonded SMS sheets help prevent microorganisms (bacteria, viruses, spores) from easily gaining access to the tray content and the two colors allow for easy identification of damage from transport and storage, playing a key role in infection prevention and patient safety.

Lotcode is printed on every application.

Reliance® Tandem combines different technologies and grammages to provide the optimal solution for sequential wrapping. Cellulose, featuring high moisture absorption, can be combined with SMS for improved strength.

Crepe paper, wetlaid and SMS can be interleaved with different colors to ensure the benefits associated to visual differentiation.