What value do we bring?

Our automated medium-size industrial process provides cost-effective and uniform impregnation of chemical formulations for consistent performance and new fiber web material features.

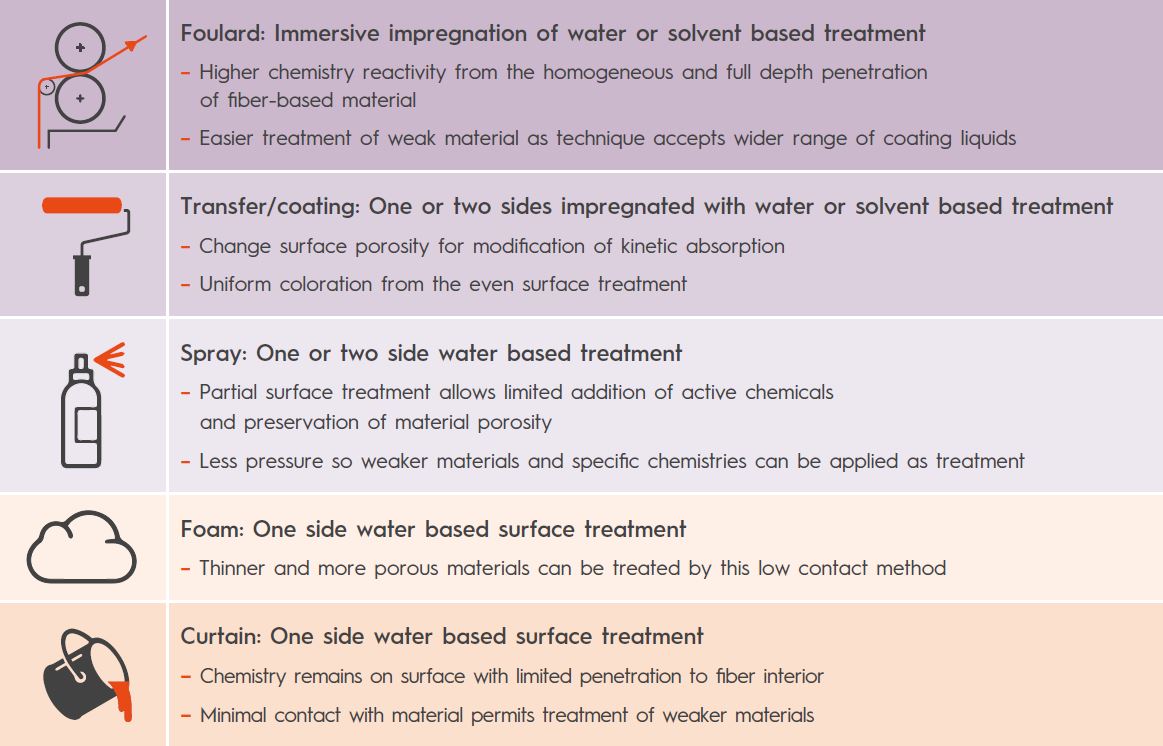

- Diversity of treatment technologies

- Automated reel-to-reel process ensuring reliable performance

- Medium to large size of finished product

- Uniform treatment with lot-to-lot consistency

- Cost saving with limited resources required and storage of treated material

- Time saving with reduced processing steps

- No chemical and waste management