Debate on wet wipes: disposal and use of plastics

Wet wipes, which are used for everything from make-up removal to baby care to surface cleaning, are familiar to most of us. These wipes are comprised of ‘nonwoven’ fiber materials and liquid or moist substances. These fibers can be derived from renewable sources, which include wood fibers or cellulose-based man-made fibers such as viscose and lyocell, from petrochemical sources, which include plastics and microplastics, or a combination of both. While there is a wide range of wipes to meet a wide range or demands, there is ongoing debate around the flushing of wipes and the use of plastics in wipes.

Ahlstrom-Munksjö produces flushable wipe base materials made from 100% renewable fiber, such as wood fibers or cellulose based man-made fibers such as viscose and lyocell. We do not use any chemicals in the production of flushable wipe materials. Our flushable wipe materials disintegrate according to accepted standards and therefore do not harm sewer or water systems. Our flushable wipe materials neither contain plastics nor chemicals and therefore do not harm the environment. Unfortunately, many consumers flush non-flushable and plastic containing wipes, which is very harmful to sewer and water systems and the environment. We, therefore, support initiatives focused on diverting the non-flushable and plastic containing wipes away from the sewer and water systems. An example of such an initiative is the recently released ‘Fine to Flush’ UK Water Industry Standard. This initiative focuses on monitoring changes in the labelling of products that might be flushed and examining the use of plastics in these products.

Sustainable Flushable Wipes at Ahlstrom-Munksjö

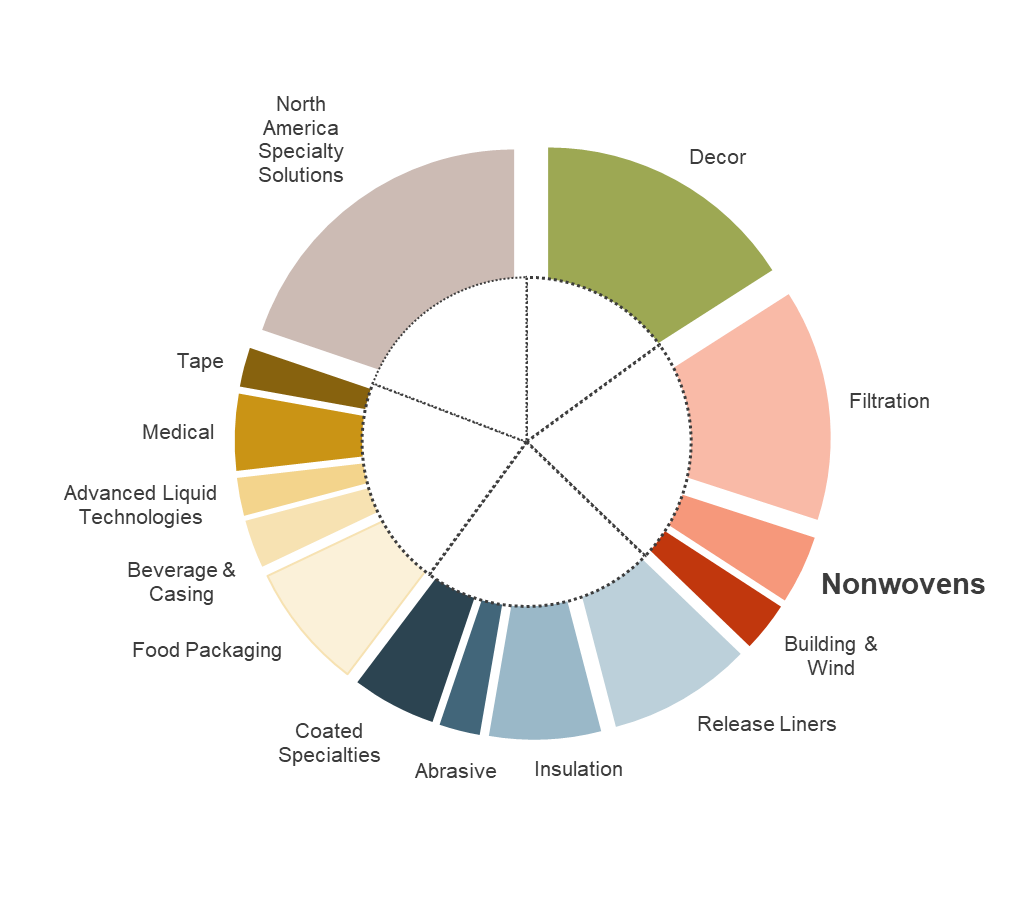

Flushable wipes is a product segment within our nonwovens business, which is part of the Filtration and Performance business area. In addition to flushable wipe material, our nonwovens business produces a wide range of products for various applications including automotive interiors, high-end wallcovers and plasterboard facers.

In 2011, former Ahlstrom divested its flushable wipes business to Suominen Corporation, a Finnish publicly listed company. However, Ahlstrom-Munksjö has continued to manufacture flushable wipe materials at its Ställdalen plant in Sweden as a contract manufacturer, through a non-binding trading setup with Suominen. The Ställdalen plant has been a forerunner in flushable wipes long before it became part of the Ahlstrom-Munksjö group.

The Market for Nonwoven Materials for Flushable Wipes

Considering the contract manufacturing set-up, Ahlstrom-Munksjö holds a significant share of the market for nonwoven material for flushable wipes: approximately one-third of the European market and approximately 10% of the global market. As a part of Ahlstrom-Munksjö’s product offering, flushable wipe materials represented merely 1% of group sales or approximately EUR 30m in 2018.

While there has been significant growth in demand - as much as 8% p.a. - driven by convenience and hygiene perception, the market environment is highly competitive due to significant excess manufacturing capacity.

In addition, there is a global consumer trend towards sustainable products, which is in part underpinned by strengthening consumer confidence and reduced economic stress, and consumers buy again with their conscience, particularly in the developed regions of the world.

Contributing to a More Sustainable Everyday Life

Our sustainability work is rooted in our code of conduct and sustainability policy and is governed by our sustainable business council.

As a participant of the UN Global Compact, we organize our sustainability work according to the United Nations Sustainable Development Goals as well as the material topics we identify and develop through dialogue with our stakeholders.

With our product offering, we facilitate a more sustainable everyday life by providing solutions that have better performance and safer materials, use fewer resources and have a lower impact than alternative options. We continue to develop sustainable and innovative fiber-based solutions with the help of our EcoDesign Tool.

We have been recognized for our sustainability performance by receiving the EcoVadis Gold Rating for three consecutive years, and we will use our sustainable product offering and sustainability momentum to expand the role of fiber-based solutions for a sustainable everyday life.

Share of Group sales