The Power of Parchment

The Genuine Vegetable Parchment (also called GVP or Parchment) is one of Ahlstrom's capabilities which gives unique functional properties to a 100% cellulose product.

Traditionally utilized for Cooking & Baking applications; a little known fact is that the Parchment Technology also supports the most demanding and sensitive usages in various industrial applications: this is the Power of Parchment.

What is Parchment?

Ahlstrom's Genuine Vegetable Parchment technology dates back to the 1840s.

Only a few producers remain worldwide for this demanding, sensitive process, which is as much an art as a science. Today, this technology has been mastered in two of our plants, both located in France.

The parchmentization process transforms cellulose, giving this natural, renewable resource plastic-like abilities. GVP is a continuous mono material; the fibers are gelled together to form a cellulosic gel, closing the surface.

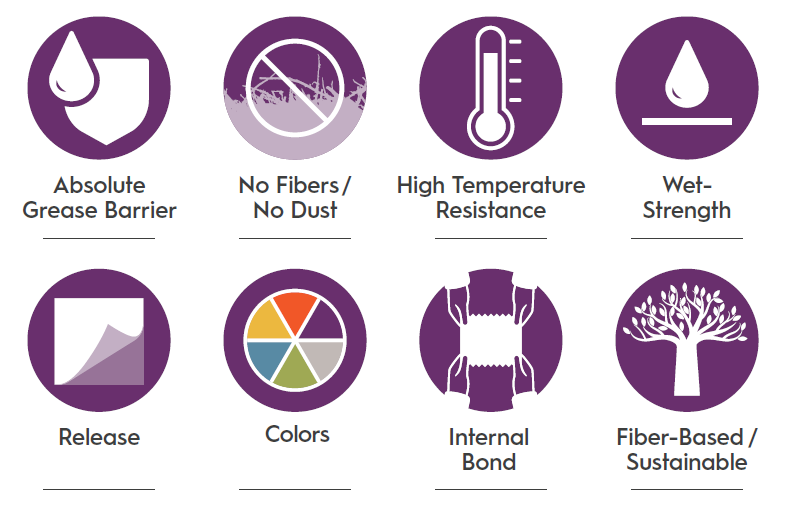

This functional substrate presents many natural attributes including exceptional grease resistance, wet strength and a clean surface: no fibers are left on it in a mono material structure, making an ally of choice in sensitive environments.

Learn more about the GVP Technology here

Where Parchment makes a difference in industrial applications

Whether used as a lamination processing aid for the PCB industry, or in aircraft cabin panels and rubber belts production, Parchment can be used in a wide variety of industrial applications where its unique capabilities make a sustainable difference.

- In Textile Tube coverings, the wide range of bleed-free, vibrant colors provides easy identification of the yarn type, and the high internal bond, grease resistance allow trouble-free spinning process and optimal performance.

- In Furniture Laminate production; our Parchment based substrate is used as the backside of a laminate and plays a functional role in the manufacturing of Continuous Pressure or High-Pressure Laminates (CPL & HPL) to produce the thinnest laminates.

- In the Smartcard prelaminated Inlay industry, using a Parchment processing aid prevents laminates from sticking to the plates, protects the chip and avoids any electrical or mechanical damage after lamination. In this application, Parchment is an exceptional replacement for the plastic films traditionally used, therefore also bringing much needed sustainability to those markets.

“In addition to its functional advantages; our Parchment also has great environmental credentials, it is made with 100% cellulose with no chemical additives, and is biodegradable and compostable,” explained Brian Oost, Vice President of the Parchment Business. “Parchment offers a multitude of possibilities for industrial applications and is an long-awaited alternative to non-renewable and fossil-based processing aids.”

Also hear Brian talk about The Power of Parchment and its versatility in our podcast: tune in here.

From innovation to production to consumer applications; discover where the Power of Parchment is harnessed today and its main advantages: find out more below