Fiber-based release liners for sustainable everyday needs

Paper release liners are efficient carriers for self-adhesive labels, adhesive materials and components. They are formed by a base paper layer – produced by Ahlstrom-Munksjö – and a silicone layer applied by our customer industries, which allows the release of the adhesive material when needed. Paper release liners are not only serving countless essential applications, their functions and features also meet the needs of sustainable everyday life.

Self-adhesive labels and self-adhesive materials can be found everywhere in everyday products as well as in very complex applications and durable equipment. Release liners enable high speed application of labels for branding of consumer goods, but also for their pricing, identification, weighting. All of them contribute efficiently to reduce product waste, increase product safety, or move goods in a secure and sustainable way through traditional or online distribution.

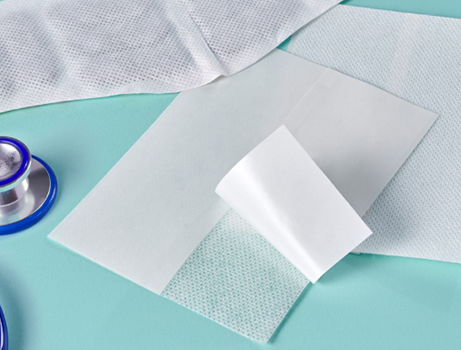

In medical applications, release liners protect plasters, transdermal drug delivery systems, or ostomy products, preserving hygiene, efficient treatments, and ultimately human health.

Release liners are widely found in double-side adhesive tapes, which are used by many industries to assemble various components or materials. In electronics, automotive or construction, adhesive bonding delivers smaller, thinner and lighter products, compared to the use of screws, rivets or other types of mechanical joining. In many cases, this allows energy and fuel efficiencies.

What makes fiber-based release liners sustainable

“Renewable resources as opposed to non-renewable, and the effects of plastic pollution are increasingly being touched on in our news. In that respect, paper release liners have an inherent advantage: they are based on cellulose derived from wood and thus fully renewable,” tells Marco Martinez, Product & Sustainability Manager, Release Liners.

Made of cellulose, release base papers are also biodegradable, and are compostable according to EN 1342. This standard assesses the physical disintegration, the quality of the final compost produced, as well as eco-toxicity.

“Studies commissioned by Ahlstrom-Munksjö showed that even with the silicone layer applied by our customers, paper release liner for self-adhesive labels remains biodegradable and compostable. This is not surprising considering that the necessary release properties can be achieved by coating less than one gram of silicone on each square meter of paper, forming a layer thinner than one micron” Martinez says.

With chain of custody certifications, renewability combines with a responsible supply chain.

“Since years, all cellulose used for our release liner products is sourced either as FSC™ certified or FSC™ Controlled Wood. This ensures that the forests and plantations in the supply chain are fully traced and managed in a sustainable way, that replanting exceeds harvesting ensuring long term protection of the resources, that human rights, biodiversity, and local communities are respected.”

Recyclability and recycling

Paper is the most recycled material in Europe, with over 70% recycling rate. Collection and recycling of recovered silicone coated liner is considered more challenging, partly due to the high volume fragmentation at the end of the supply chain, and also due to presence of silicone. A considerable quantity is already being recycled today despite those challenges, whether through separate collection for liner-specific programs, or through the collection streams for mixed paper and cardboard. Release papers are made of high quality fibers and contain no fillers, which makes them a valuable recovered paper source. The presence of the very thin silicone layer is technically processable in paper manufacturing equipment with deinking technology.

In 2019, the technical branch of the Italian pulp and paper industry association Assocarta has developed a norm (UNI 11743:2019) for evaluation of paper recyclability in industrial processes, through laboratory simulation of the main phases of industrial papermaking. According to this test, silicone coated release paper used for self-adhesive labeling resulted recyclable with paper, with positive scores in the parameters assessed.

“With these test results and with the further increase of collaboration we currently see in the supply chain, there are opportunities to further increase recycling rates for paper release liners,” says Marco Martinez.

In 2020 Ahlstrom-Munksjö joined CELAB, (Circular Economy for Labels), a global coalition formed in order to create greater recyclability for the products in the self-adhesive label industry, by enhancing and promoting options for recycling their waste streams around the world.

As a global supplier of release liner papers, Ahlstrom-Munksjö takes part in the coalition’s global steering committee as well as regional branches in Europe and North America. The company also looks forward to further expand the program into other regions where it operates.