Plasma separation: Why do you need it and how do you achieve it

Written by: Stephanie Pigeot-Remy, PhD and Tonia Showers in partnership with DCN Dx

Analyzing the components of blood is a key diagnostic step in the detection of diseases and accurate separation of plasma from blood cells plays a crucial role in the precision of a lateral flow diagnostic test.

Why do you need Plasma Separation?

Lateral Flow Devices are a rapid, inexpensive, and simple diagnostic tool intended to be utilized at the point of care. Due to the simplicity of use and rapid results obtained, the list of assays being utilized on this platform is ever expanding. As the types of LFA’s expand, there is increasing demand for the use of whole blood as the sample matrix. Being able to separate the plasma from cells and generate sufficient quantity of plasma is one of the most basic, central and crucial steps in the field of diagnostic to maximize performance of the test devices. Utilizing a blood separation step minimizes the interference of cells in the process of analyte detection while improving sensitivity and selectivity of the assays in lateral flow tests.

How do you separate the plasma?

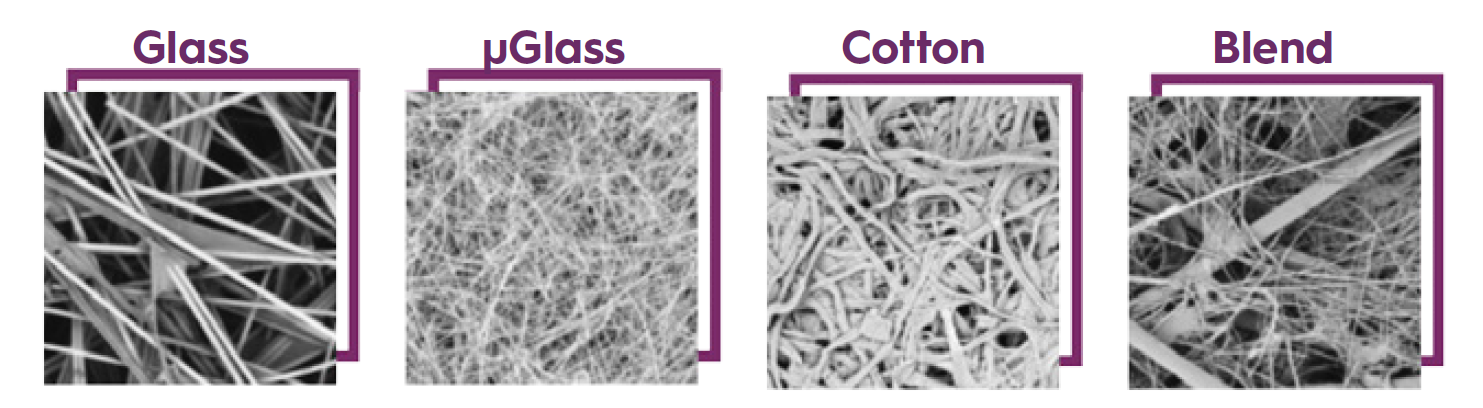

Generally, plasma can be separated from a whole blood sample by mechanical methods using sedimentation or centrifugation, which requires a laboratory setting and additional equipment for sample processing. A very attractive alternative technique that can be adapted for POCT test strips utilizes fiber based filtration membranes that can be incorporated directly into the LFA test strip and do not require any additional equipment or sample processing. Vertical or lateral filtration methods using fiber based filtration membranes have been successfully employed for decades in lateral flow devices.

In general, the lateral filtration techniques of plasma separation can be classified in two different categories:

- Biochemical filtration: This method consists of applying a pretreatment to the sample pad (commonly made of glass fibers) to agglutinate red blood cells and allow the plasma to further flow along the conjugate pad and into the nitrocellulose membrane.

- Mechanical filtration: This method relies upon the fibrous components and porous matrix, as well as, the specific pores size distribution, optimized for red blood cells retention.

In order to achieve the best separation results, you need to consider the fibrous components, physical properties, sample volume and potential limitations that need to be considered.

How to choose the right plasma separation pad?

When it comes to lateral filtration for plasma separation, the key physical characteristics of fiber-based materials that need to be considered to get good and sufficient quantities of plasma are the absorption capacity linked to the thickness of the plasma separation pad, the red blood cell retention capacity and the overall dimension of the pad for the sample volume.

For a fixed volume of blood, as thickness of blood separation pads increases, amount of recovered plasma decreases. However, by using appropriate pads dimensions and a specific chemical treatment, significant improvement in plasma recovery can be achieved.

If the correct fibrous components are not chosen, hemolysis or rupturing of the red blood cells can occur. Hemolysis of any type should be limited within the diagnostic tests, as the rupture of the cells leads to the release of hemoglobin molecules, causing the serum or plasma to have a pink to red color, thus making the readout difficult to judge.

Leakage of the cells content along the membrane can also cause problems such as low sensitivity, selectivity and inaccurate results. One of the main reasons causing hemolysis can be the use of an inappropriate type of glass separator pads, especially the ones with small diameter glass fibers.

Ahlstrom-Munksjö Plasma Separation offering:

Ahlstrom-Munksjö original single layer blood separator, CytoSep®, was developed in early 1990’s to address industry demand for whole blood testing. Working closely with our customer base we continued to develop improved fiber-based materials and methodically upgrade the performance of CytoSep®, meeting the increasing demand for sensitivity, consistency and non-interference. CytoSep® is widely used for rapid separation of plasma from whole blood samples in lateral flow applications, retaining blood cells while allowing serum to flow rapidly.

There are three historical grades which differ in thickness: CytoSep® 1663, CytoSep® 1662, CytoSep® 1660. These untreated media contains no chemical-interfering substances and show no significant binding of plasma components.

Going into our 4th decade of developing improved and innovative components for Lateral Flow Immuno Assays, we continue to lead the industry providing new materials capable of keeping pace with this rapidly evolving industry.

The newest CytoSep® products, HV 1667 and chemically treated HV Plus 1668, are designed to separate increased volumes of whole blood within the same area of media while limiting hemolysis.

Focus on:

CytoSep® HV plus 1668 combines both chemical and mechanical filtration processes for higher performance. The chemicals help to deform shape of red blood cells and so limit their diffusion while the specific pore size blocks the residual mobile RBC. On a defined sample pad area, CytoSep® HV plus 1668 is able to accept 25% more in whole blood volume compare to traditional plasma separation pads.

Key Features:

- Faster blood absorption and plasma separation

- Higher plasma yield for increases in line sensitivity

- Designed with hemolysis prevention in mind

- Ability to separate larger volume blood samples so that less material can be used in new designs

More blood - more plasma - more analytes - higher sensitivity

Discover more about Ahlstrom-Munksjö CytoSep® and other plasma separation pads!