Supporting our customers’ sustainability ambitions with Ahlstrom BioSpun™, our spunbond PLA

In an era where environmental awareness is becoming increasingly important, businesses worldwide are actively seeking sustainable alternatives to reduce their environmental impact. We, Ahlstrom, pioneered BioSpun™ spunbond PLA, a high-performance solution to address the challenge of reducing dependency on oil-based polymers in nonwoven materials, more than 15 years ago in our UK facility and based on our expertise, are now looking to expand its usage and applications.

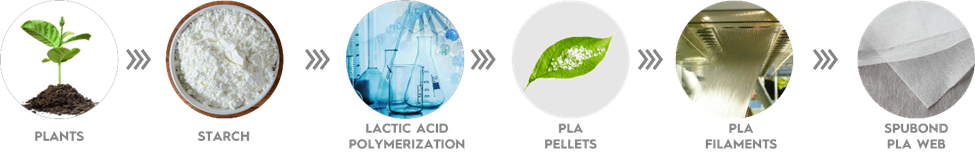

Understanding PLA: a polymer made from renewable raw materials

Poly Lactic Acid (PLA) is a biobased polymer derived from sugars extracted from annually grown plants, such as corn (maize) or sugar cane. What makes PLA truly exceptional is its sustainable nature, as its raw material source can also originate from other biomaterials like agricultural wastes and non-food plants. By utilizing renewable resources, Ahlstrom's BioSpun™ contributes to a circular economy, reducing the dependence on fossil fuels.

PLA is classified as a biopolymer or bioplastic, with a melting temperature comparable to polypropylene, a widely used conventional plastic. Like other polymers it can be processed into films, fibers, and filaments, either on its own or in combination with other materials like biopolymers PHA, PCL, or cellulosic fibers.

Advantages of BioSpun™ spunbond PLA

- Renewable Raw Materials: Being derived from renewable resources, BioSpun™ PLA contributes significantly to reducing the dependence on fossil-based polymers.

- End of life: Unlike traditional oil-based polymers, BioSpun™ PLA can naturally break down over time, leaving behind no harmful residues. Its compostability ensures responsible waste management. BioSpun™ is certified biodegradable in soil and industrially compostable in soil by DIN-CERTCO, adhering to the EN13432 norm. BioSpun™ is also recyclable.

- Water-efficient manufacturing: Ahlstrom's spunbond PLA production process requires no water usage, conserving precious water resources compared to wetlaid processes.

- Manufacturing versatility: Spunbond PLA can substitute traditional plastics without a change in equipment & machinery, making it an ideal material to rapidly evolve our customer’s product offering towards sustainability. BioSpun™ also offers the advantage of lower sealing temperatures compared to oil-based plastics, reducing energy consumption during the manufacturing process.

Learn more about the BioSpun™ Technology here

Functional Properties of BioSpun™ spunbond PLA

BioSpun™ PLA exhibits a range of functional properties that make it an attractive alternative to conventional plastics:

- Permeability/ breathability: One of the most valuable aspects of the material is that it presents a very open structure, allowing good permeability/breathability.

- Strength: Despite the light grammage, BioSpun™ is a very strong structure, which can be a benefit in most applications.

- Food grade: BioSpun™ is food contact approved, making it suitable for a wide array of food & beverage but also personal and medical care applications.

- Transparency: The material is transparent, making it suitable for various applications where visibility is crucial.

- Neutral odor and taste: BioSpun™ PLA does not affect the odor or taste of the contents, ensuring the preservation of product quality.

- Soft to the touch: The non-woven material feels soft to the touch, providing comfort and enhancing the user experience.

- Sealability and thermoformability: BioSpun™ PLA can be sealed using heat or ultrasonic methods on one or both sides, and can also be thermoformed, making it versatile and adaptable to different product requirements.

Current Applications and Customized Solutions

BioSpun™ spunbond PLA opens a wide range of applications across various industries and markets :

- Tea bags: Ahlstrom offers PLA-based "BioWeb®" tea bags, providing an alternative to traditional tea bags.

- Coffee market: Solutions for coffee capsule lidding and filters help reduce single-use plastic waste.

- Horticulture: Spunbond PLA acts as a mulch, offering biodegradable crop protection and weed control.

- Medical: BioSpun™ PLA is suitable for personal face masks.

- Thermo-insulation bags: BioSpun™ PLA is suitable for thermal insulation and shipment protection, replacing styrophane for example.

The versatility of BioSpun™ spunbond PLA allows customization based on specific needs:

- Grammage and dimension range: BioSpun™ PLA is available in a wide range of grammages and widths, ensuring suitability for various applications.

- Non-GMO PLA: Ahlstrom provides the option for non-GMO PLA for applications requiring specific certifications.

- Coloration: The material can be customized in various colors, adding aesthetic value to products.

- Surface aspect and properties: Additives and surfactants, or flat calandering can be used to bring a final touch to the product.

Considering Future Applications

As we look ahead, there is a huge market potential for BioSpun™ spunbond PLA in different end uses like Food Packaging, Medical Textiles, Agriculture, Filtration, Automotive, Apparel, Hygiene Products, Horticulture, Furniture, Construction, and more! “The main developments to broaden the scope of this new generation of polymer, representing an alternative to fossil-based plastics are to work on the softness, the elongation capability and most of all, optimizing its end of life to reach home compostability.” explains Mathilde Leroy, Business Development Manager for Ahlstrom. “To achieve theses ambitious goals, collaborative innovation across the value chain will be key.”

“By engaging in partnerships, fostering research, and supporting sustainable initiatives, businesses can collectively explore new applications using BioSpun™ spunbond PLA. The versatility of this biopolymer paves the way for a greener and more sustainable product portfolio.” highlights Christian Reiter, head of sales.

In conclusion, Ahlstrom's BioSpun™ spunbond PLA represents a significant step towards supporting brands' sustainability ambitions maintaining the performance of the material. As more companies embrace this solution, we move closer to a circular economy and a brighter tomorrow. By choosing BioSpun™, businesses can contribute to positive environmental change and shape a more sustainable world for generations to come.