How to handle rolls correctly?

To achieve a good unloading, you need the right tools to handle well. In our side, we are using a “clam shells forklift”. They allow the rolls to be moved from a standing position to a lying position or vice versa. We use forks weighing 2.5 to 3 tons. The clams shells (clamps) are set up to 160 bars. The roll must be placed in the middle of the clamp in order to not damage the roller or the clamp itself.

To achieve a good unloading, you need the right tools to handle well. In our side, we are using a “clam shells forklift”. They allow the rolls to be moved from a standing position to a lying position or vice versa. We use forks weighing 2.5 to 3 tons. The clams shells (clamps) are set up to 160 bars. The roll must be placed in the middle of the clamp in order to not damage the roller or the clamp itself.

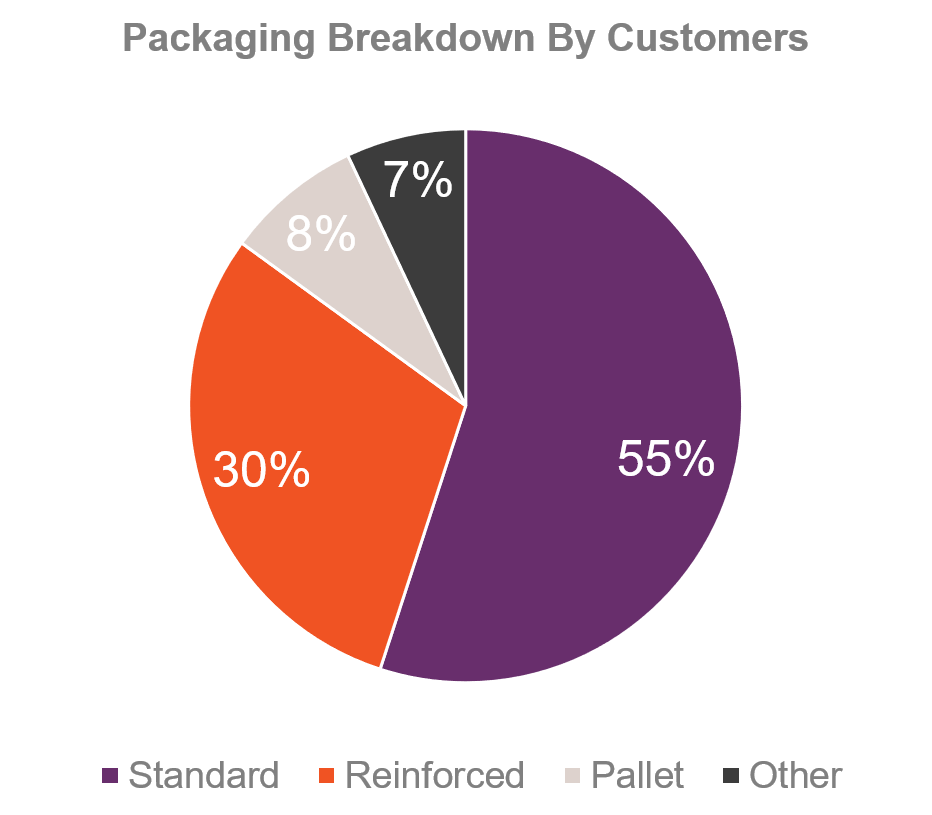

Other tools are possible, that's why we offer different types of packaging. In addition, there are always customization solutions. 55% of our deliveries are made with what we called “standard packaging”: it’s a double packaging. First layer: a plastic foil in order to protect against environmental variations, especially moisture variations. On top of that, we have a Kraft to protect the circumferences and the edges from handling. 30 % of our deliveries are made with reinforced packaging: we are putting additional layers of kraft or cardboard on the circumference of the reels to be even stronger. 8% of our deliveries are on pallets (for forklift use).

Other tools are possible, that's why we offer different types of packaging. In addition, there are always customization solutions. 55% of our deliveries are made with what we called “standard packaging”: it’s a double packaging. First layer: a plastic foil in order to protect against environmental variations, especially moisture variations. On top of that, we have a Kraft to protect the circumferences and the edges from handling. 30 % of our deliveries are made with reinforced packaging: we are putting additional layers of kraft or cardboard on the circumference of the reels to be even stronger. 8% of our deliveries are on pallets (for forklift use).

7% are specifics ones (customized packaging), for example, if you use a spur truck, we can change the wooden plug to a plastic one. In addition, we use a tool to show where is the middle of the core in order to help the nail of the spur truck right in the middle of the roll. The rolls can thus be unloaded in good conditions and in safety.