The maker installation

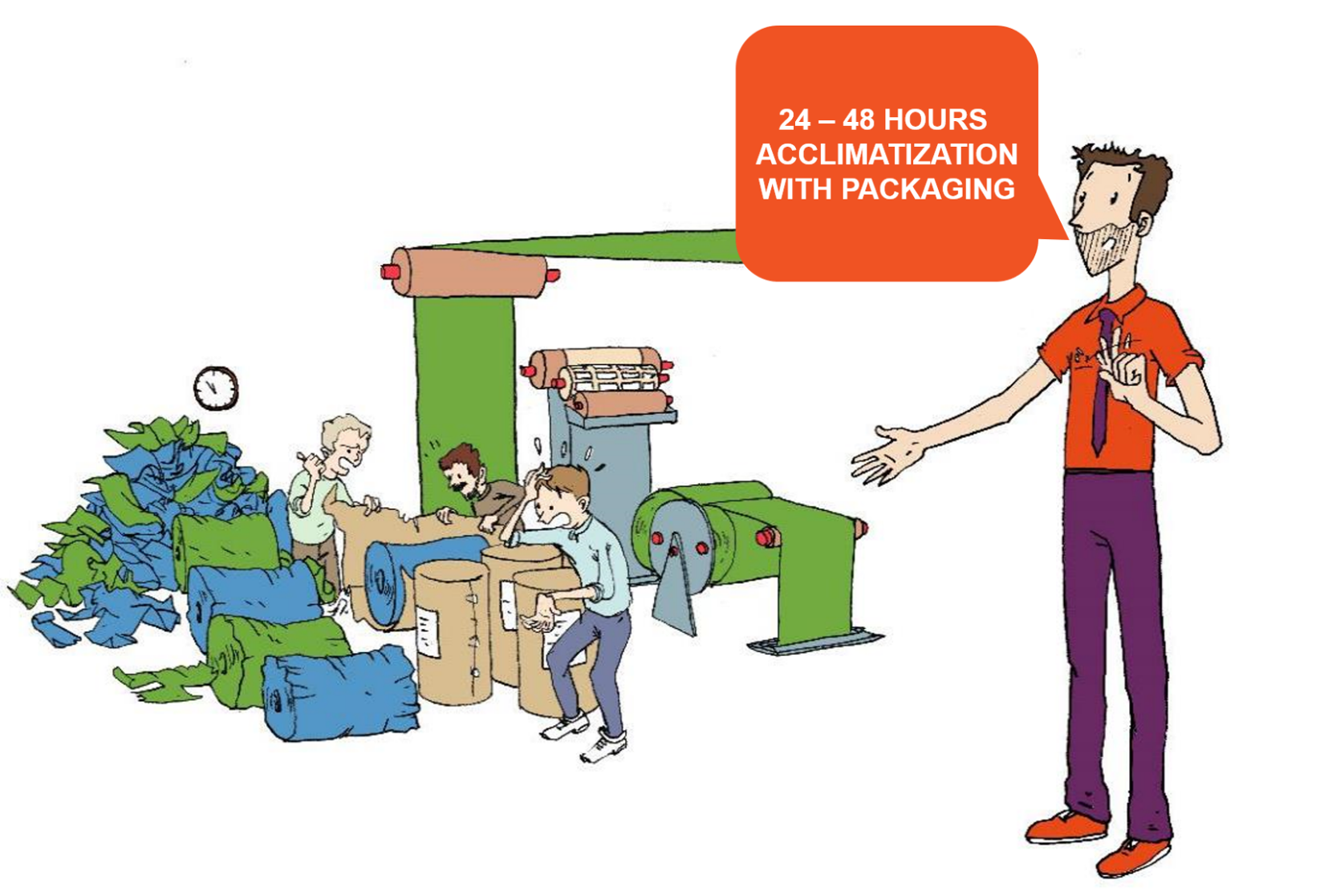

First thing is to consider that paper is sensitive because it’s an alive material (made with wood fiber mainly). If you have big climatic differences between the place where you are storing paper and the production area (maker), this is very important to consider an acclimatization time. It can last more than one day if needed. Acclimatization must be done without unpacking. Precisely, the paper must be unpacked at the very last moment before use. Pay attention to these two points!

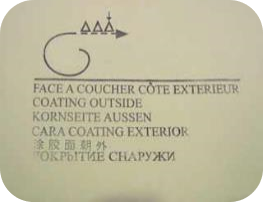

There is always a stamps on the edge of every roll, it is to remind you that our products are not symmetric papers, there is always:

-a coating side designed to be well adapted to the bonding and to get good grits adhesion

-a printing side well adapted for printing but also remoisturizing which is very important to be well done after the flexing

The stamp is here to be sure using the right side of the paper.

An other important indication is splices: a red tape on the edge of the roll indicate where it is. Normally all the necessary information can be found on our labels. If you want to see specific indications appear on the labels, do not hesitate to ask us customization.