Buffing process: view from tannery Rémy Carriat

What types of buffing do you practise?

There are two types of buffing, or sanding, depending on what you want to achieve. First of all you can sand the leather to correct or remove the grain, especially when the initial quality of the skin is not good enough, or in order to obtain a uniform pattern and eliminate certain blemishes, hence the term “corrected grain”. This operation is a less qualitative operation as it implies that the raw material used was not of the highest quality. Then there is what we call “sublimation buffing”, which is considered essential to give the leather its optimum aesthetic quality: in fact this is the only type we practise. The grain is buffed lightly to create a nubuck finish: this gives the leather a velvety appearance and makes it soft and silky to the touch.

How do you go about this buffing process?

We are extremely rigorous in selecting our skins and we only sand them to get the desired finish. This buffing process takes place in a single pass. We use very fine grit (P240) to skim lightly over the grain, which acquires the characteristic pile of a fine nubuck. Only the surface is cleaned, which ensures the leather retains the beauty and finesse of its natural grain. The skin can then be hotstamped to obtain visual effects, wrinkles, holes, perforations, etc. - the possibilities are endless!

Creating nubuck, step by step

1) Selection of hides purchased at the “wet blue” stage. Wet blue leather is leather that has been mineral tanned, but not yet dyed or fatliquored

2) Fatliquoring of the skin with animal and plant oils to make it supple and soft

3) Dyeing by immersion in dye baths in rotating drums, which guarantees deep, bright colours

4) Dressing of the skins to increase their resistance in use

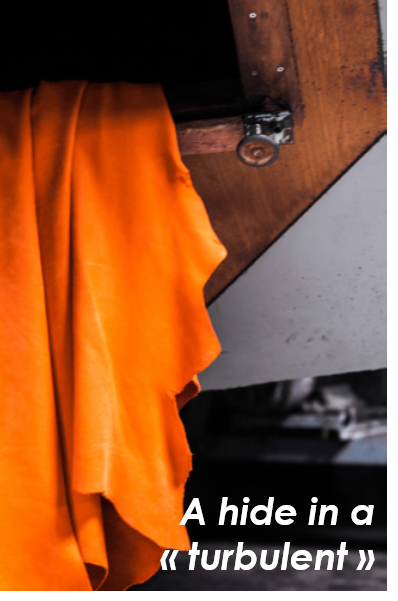

5) Buffing using a cylinder with a strip of very fine grit sandpaper. The entire hide is treated in a single pass, before being sent back to the dyeing shop to remove the dust and ensure the colouring is uniform. It can then be hot-stamped and softened again in a large rotating wooden box, known as the “turbulent”