The leather production process

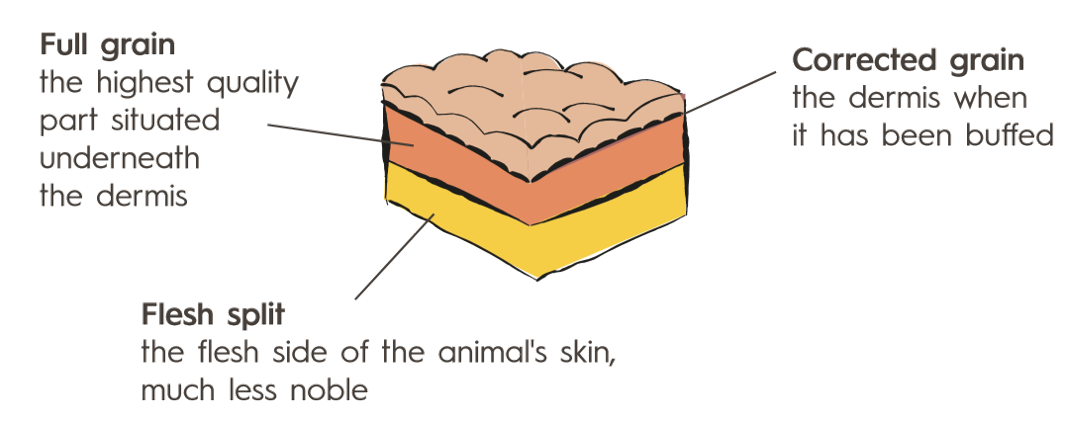

Non-exotic leather is made from animal skins and is therefore a way of recycling an animal by-product. These skins are made up of the epidermis, the dermis and the hypodermis, which consists of adipose tissue. The dermis has three layers, which define different qualities of leather:

First of all the skins are cured with salt to remove the water from the tissues and halt the development of micro-organisms, then dried. 15 days later they are examined and sorted according to various criteria (thickness, blemishes, weight, surface, etc.) before being entrusted to the tannery, which will put them through a 5-stage process to bring out all their nobility and beauty:

1) Beamhouse operations

The different steps in what are known as beamhouse operations - the steps between curing and tanning - take place in a succession of enormous drums. After soaking (rehydration) and cleaning, unhairing and fleshing, the skins undergo bating, a softening process to prepare them for tanning.

2) Tanning

Using tannins, which are substances containing vegetable or mineral salts or a combination of them, the skins are transformed into rotproof leather (i.e. which cannot decompose), which is resistant to hot water and has a low water content.

3) Dyeing

The skins are dyed wet in large drums. The leather is also fatliquored to give it suppleness and strength.

4) Dressing

The dyed leather then undergoes setting-out to stretch it and drying, before being sorted for quality. It is also at this stage that leather can be buffed to obtain nubuck.

5) Finishing

This stage consists of colouring the leather surface to give it its final appearance. Different methods are used, which will impact the quality of the finished product:

- After being coloured by immersion in a dye bath, aniline leather, which has a fine natural finish, does not undergo any surface treatment. It is a leather that lives with its user.

- Semi-aniline leather is covered with a slightly opaque layer of pigment and another layer of translucent material, which masks minor defects and harmonises the colouring.

- Leather with a pigment finish, is sprayed with pigment, making it easycare and insensitive to water.

- For corrected grain leather, pigment is applied to skins that have been buffed (sanded). This is a way of “re-creating” a grain finish.